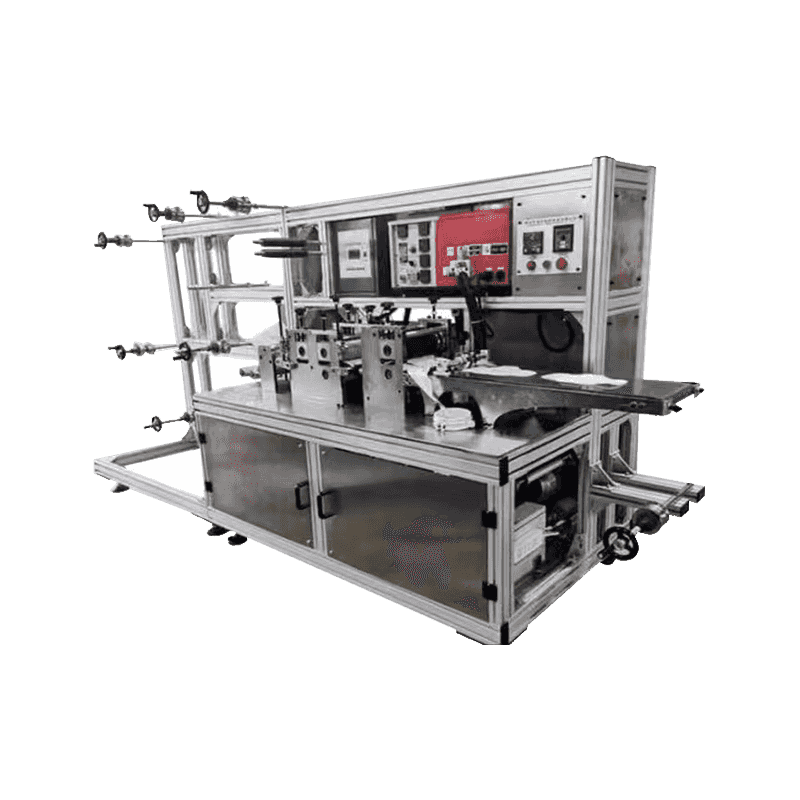

Disposable Products Machine

Sanitary napkin machine with glue coating function

Product Function Introduction

1. This machine is used for sanitary napkin production, with PLC control system for easy operation, high efficiency and energy saving.

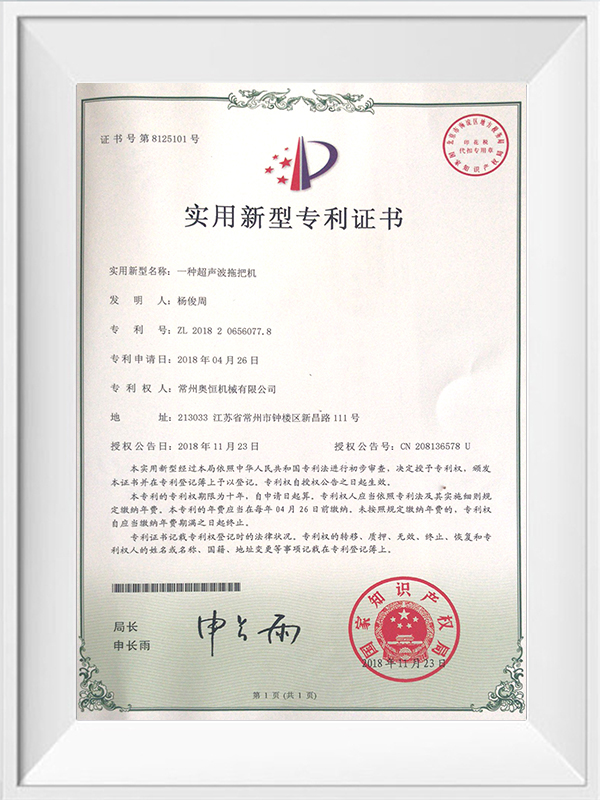

2. Using ultrasonic principle and high hardness special steel roller mold contact, wireless sewing and welding cutting, no need to heat, use life is 10 times longer than the traditional mold.

life is 10 times of traditional molds. Flatter, more beautiful, no wrinkles.

3. High power frequency conversion motor transmission, stable speed, adjustable

4. Automatic negative ion (blue core) patching machine, size 80*30mm.

5. This machine has automatic backing and release paper attachment function, more efficient and easy to operate.

6. Sanitary napkin size (L*W): 360*160mm, 410*160mm two sizes;

7. The machine has automatic counting function and stops when it reaches the set production.

8. The machine is equipped with 6 cloth feeding rollers, and the tension of each feeding roller can be adjusted individually.

9. Suitable for PP nonwoven, hot air/breathable nonwoven, PE film, SAP paper, SS hydrophilic nonwoven and so on.

10. High power ultrasonic power is strong and adjustable, suitable for different material thickness and welding.

11. Adopting advanced high-speed motor strong output (negative pressure pumping to discharge the waste material), ultrasonic power can be adjusted according to the fabric.

12. The use of automatic frequency tracking system, built-in computer chip multi-channel ultrasonic automatic protection system to ensure the safety and stability of the host.

13. This machine is a fully automatic machine, which contains the stamen heart and the other side contains adhesive strips and stickers, a molding product size. Pattern. Shape. etc. can be changed according to customer needs

English

English 中文简体

中文简体 русский

русский Español

Español