Slitting Machine

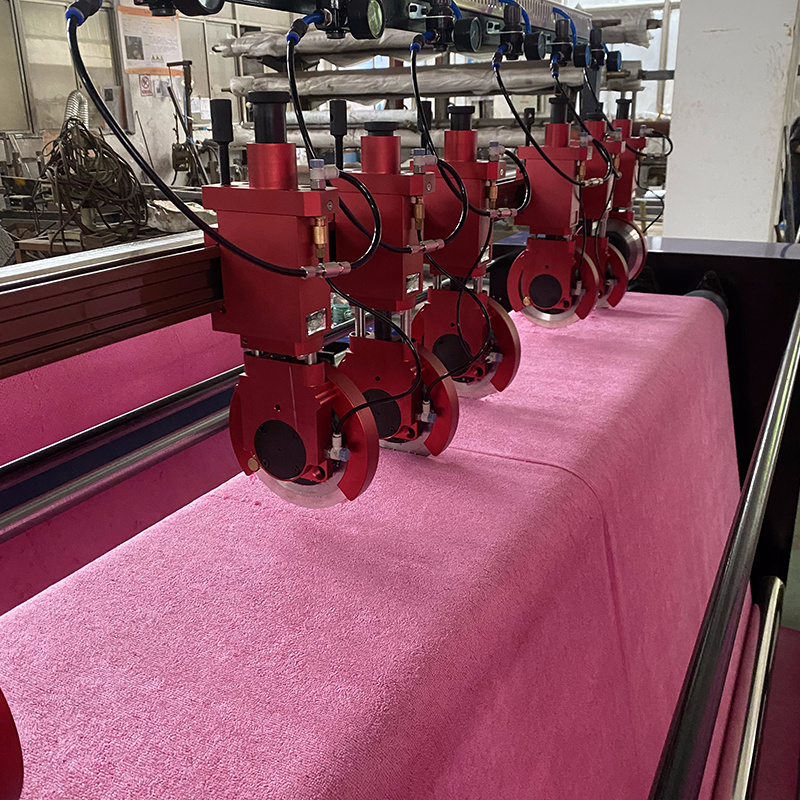

Shear type air cutter slitting machine

1. The electronic control adopts centralized control, which is easy to operate and aesthetically pleasing

2. Adopting Shenzhen Yuanxin brand frequency converter control system, stable and reliable

3. Brushless automatic correction basket material placement, convenient and easy to operate for material placement

4. Automatic edge suction control system

5. The automatic spreading roller unfolds the folded fabric

6. Double drum tension winding

7. Bilateral waste collection device

8. The mechanical structure is strong, with high stability for high-speed operations, effectively improving the durability and service life of the machinery

Five: Operation precautions

1, before starting, ensure that the voltage, current and pressure equivalent is correct and stable.

2. Before the equipment is ready for operation, all personnel must inform to leave the equipment to ensure personal safety before starting operation.

3, When the scuttering machine is running, do not touch the film roll or rubber roll in operation with your hand, so as not to involve your hand and cause personal injury. (No cotton gloves)

4, when the machine equipment is running, it is strictly prohibited to touch the gear chain and other transmission parts with hands, clothing cuffs, so as to avoid injury accidents. (No cotton gloves)

5, in the operation process, do not use a knife or hard object to scratch, cut each roll core.

6, regular maintenance of the machine and equipment, and check whether the functions are normal.

7, the occurrence of machine equipment failure, should promptly notify professional maintenance personnel, private maintenance is strictly prohibited.

8, Press the power switch or emergency stop switch when the equipment is in an emergency state or an accident is considered

English

English 中文简体

中文简体 русский

русский Español

Español