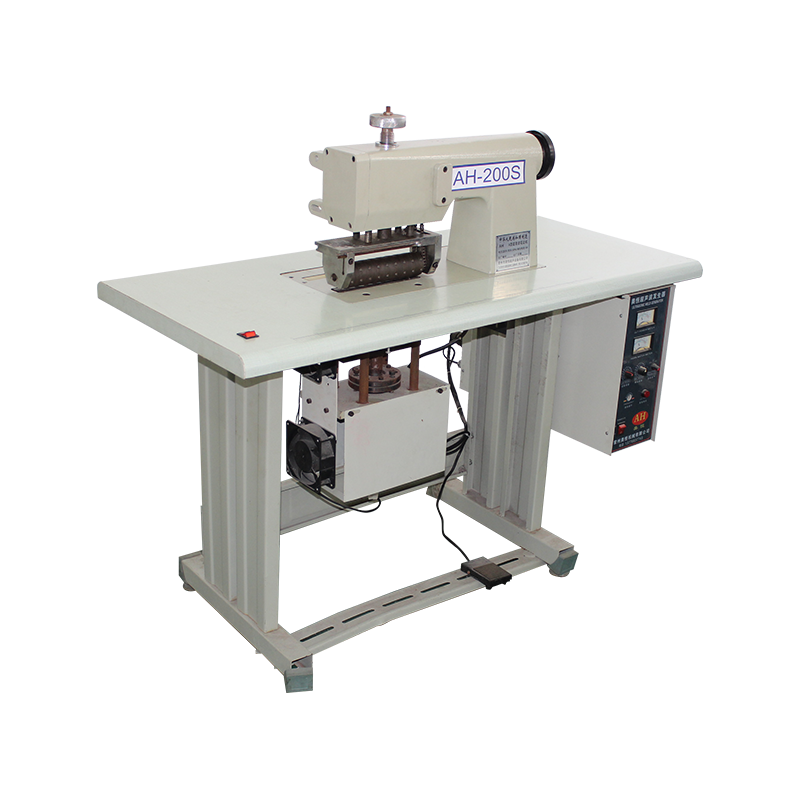

Ultrasonic Lace Machine

AH-200Q/S Three-speed power adjustment function ultrasonic lace machine

Basic configuration:

1. New computer intelligent ultrasonic generator;

2. The original process of 18KHz bottom mold fixed suspension mechanism is made of six wafer combinations, and the output is stronger;

3: Manual pneumatic pattern mould lifting system;

4: Double-tube rack, ordinary desktop version, large single head;

Features of this machine:

1. The ultrasonic power is large, up to 2500W, and has three power adjustment functions to adapt to the welding and cutting requirements of different materials and thicknesses;

2. Built-in computer chip and multi-channel ultrasonic protection system to ensure the safe and stable operation of the host;

3. Unique patented technology, 18Kz transducer, 6 piezoelectric ceramic oscillators, super output;

4. Various patterns and patterns, which can provide design according to customer needs;

5. The running speed is four times that of ordinary sewing machines, and the operation is simple,

Function

1. Trimming: unilateral straight or curved excision, and edge dissolution treatment, so that the edge is smooth and smooth, not rough, and no burrs;

2. Stitching: two or more layers of fabric are sewn together, wireless needle-free instead of sewing and good welding strength;

3. Perforation: cut out the holes of various flower types and do edging treatment;

4. Strip opening: single or multiple strips of material are cut at the same time, and the edge is melted without burrs;

5. Forming: cutting, suturing and embossing at the same time to make the product form at one time.

Scope of application:

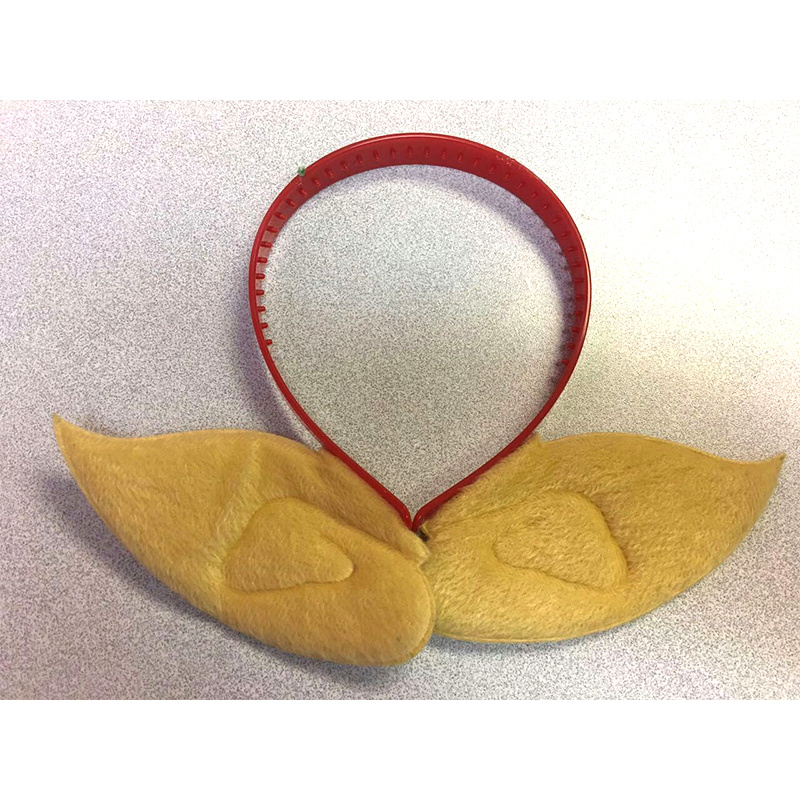

all kinds of chemical fiber fabrics, all kinds of artificial leather, non-woven fabrics, spray cotton, thermoplastic films, chemical plastic sheets, wedding accessories, medical eye pads Suitable for making 9 cm coasters, filter materials, special masks, hairpin headwear, craft flowers, Christmas ornaments, extra-wide lace, etc.

English

English 中文简体

中文简体 русский

русский Español

Español