Disposable Products Machine

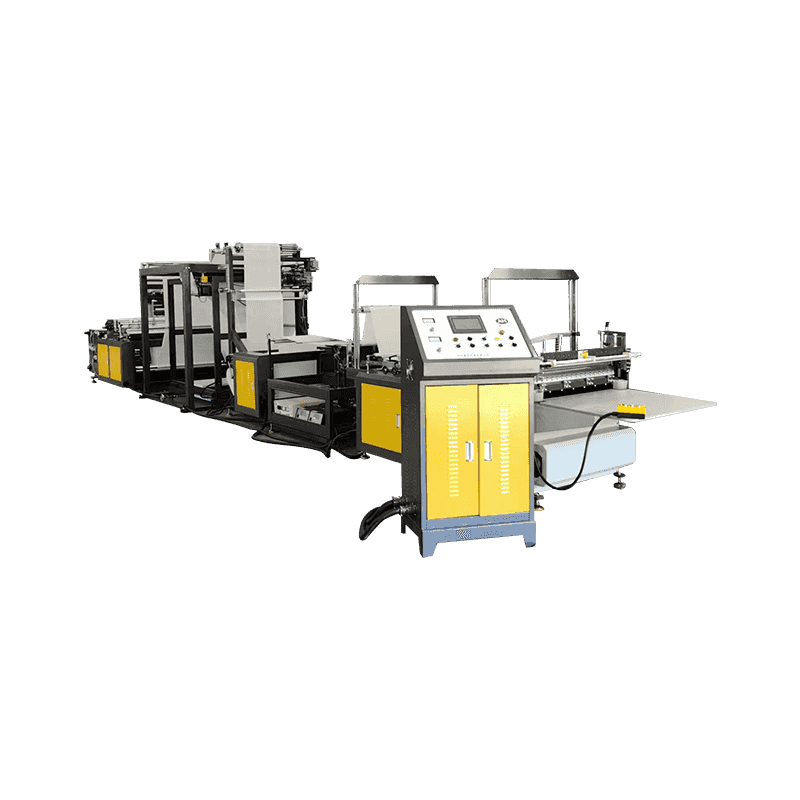

Non-woven pillowcase machine

Non woven pillowcase machine is a specialized equipment used for producing non-woven pillowcases. It has the characteristics of high degree of automation and high production efficiency. This machine integrates multiple advanced technologies to achieve automated production processes from raw non-woven fabric rolls to finished pillowcases. The following is a detailed introduction to the non-woven pillowcase machine:

1、 Product Features

High degree of automation: The non-woven pillowcase machine can achieve a fully automated production process from feeding to finished products, including folding, ultrasonic bonding, cutting, bag making, counting, stacking and other steps, greatly improving production efficiency.

High production efficiency: Due to its high degree of automation, the non-woven pillowcase machine can complete the production of a large number of pillowcases in a short period of time, meeting market demand.

Easy to operate: The equipment is mostly operated by touch screen PLC, equipped with servo driven fixed length, photoelectric tracking and other industrial control devices, making the operation more convenient and fast.

Stable quality: Machine production ensures that the size, shape, and quality of each pillowcase are consistent, reducing errors caused by human factors.

Flexible configuration: According to different production needs, the non-woven pillowcase machine can be adjusted to meet the design requirements of non-woven fabrics and pillowcases of different specifications and materials.

2、 Production process flow

The production process of non-woven pillowcase machine is roughly as follows:

Feeding: Place the non-woven fabric roll in the designated feeding position, and the machine will automatically feed it into the production line.

Preprocessing: may include preparation work such as flattening and positioning of non-woven fabrics.

Folding: According to the set program, the machine folds the non-woven fabric into the initial shape of the pillowcase.

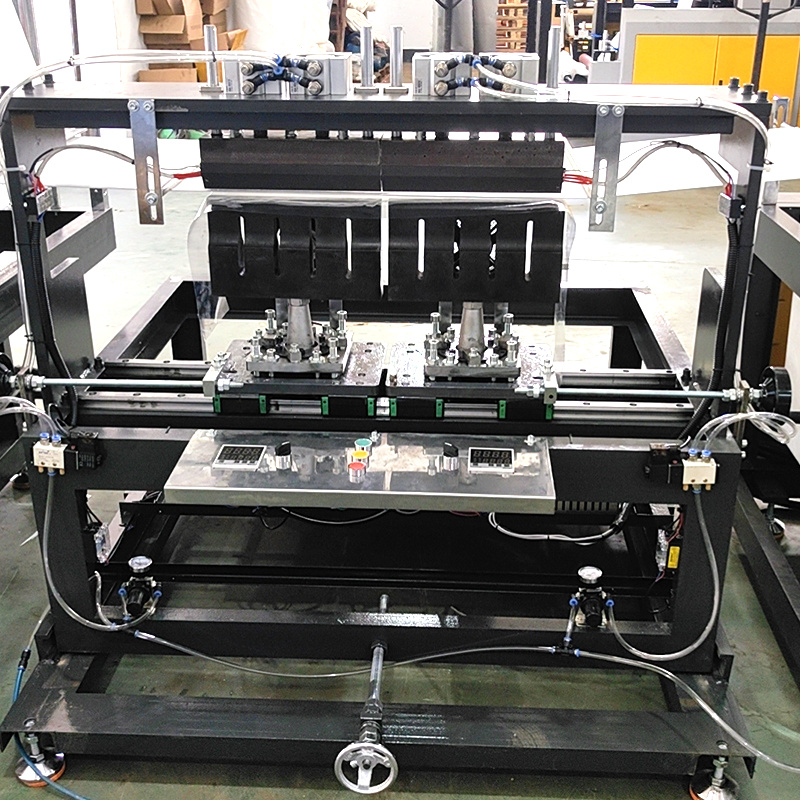

Ultrasonic bonding: Using ultrasonic technology to bond non-woven fabrics together.

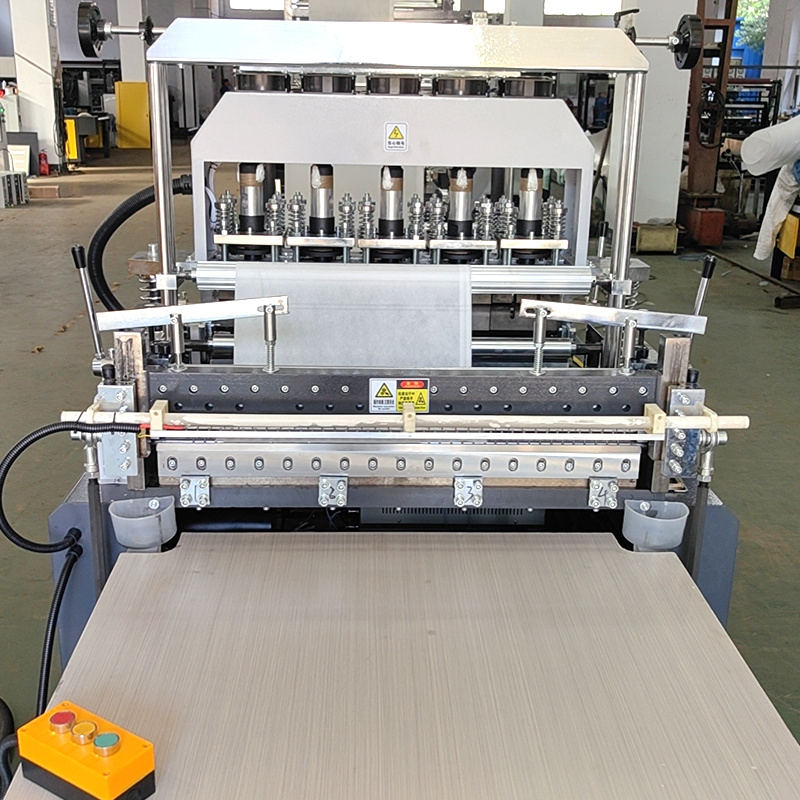

Cutting: Cut the bonded non-woven fabric according to the set size.

Bag making: Cut non-woven fabric into pillowcases.

Counting: Counting the pillowcases produced.

Stacking: Stack finished pillowcases for easy packaging and transportation.

English

English 中文简体

中文简体 русский

русский Español

Español