Disposable Products Machine

Ultrasonic Glove machine

Working principle

The ultrasonic glove machine utilizes the high-frequency vibration and thermal energy

Workflow

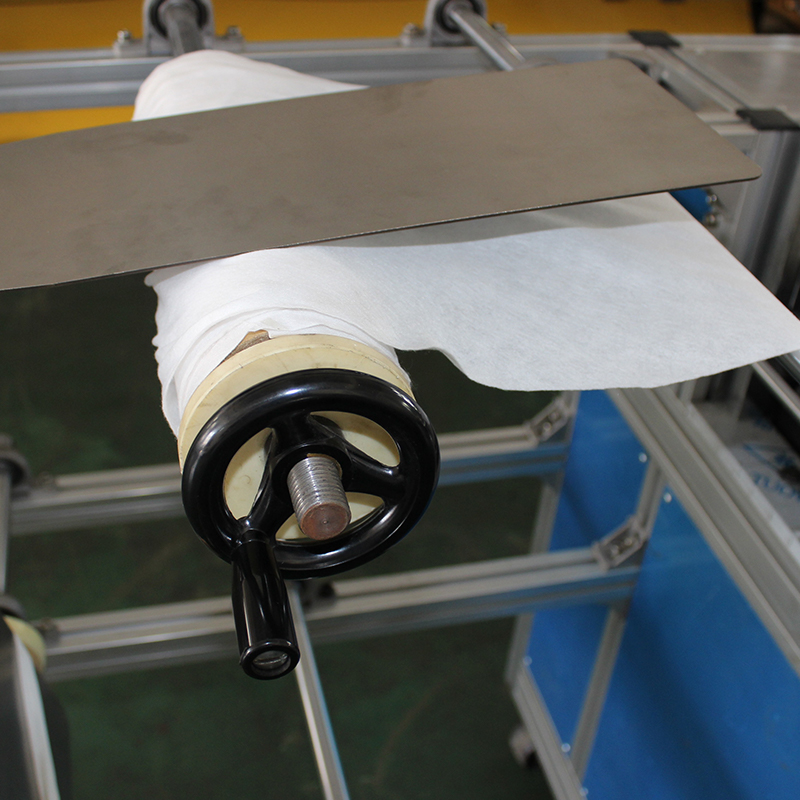

1. Material preparation: Prepare non-woven fabrics, synthetic fabrics, and other materials

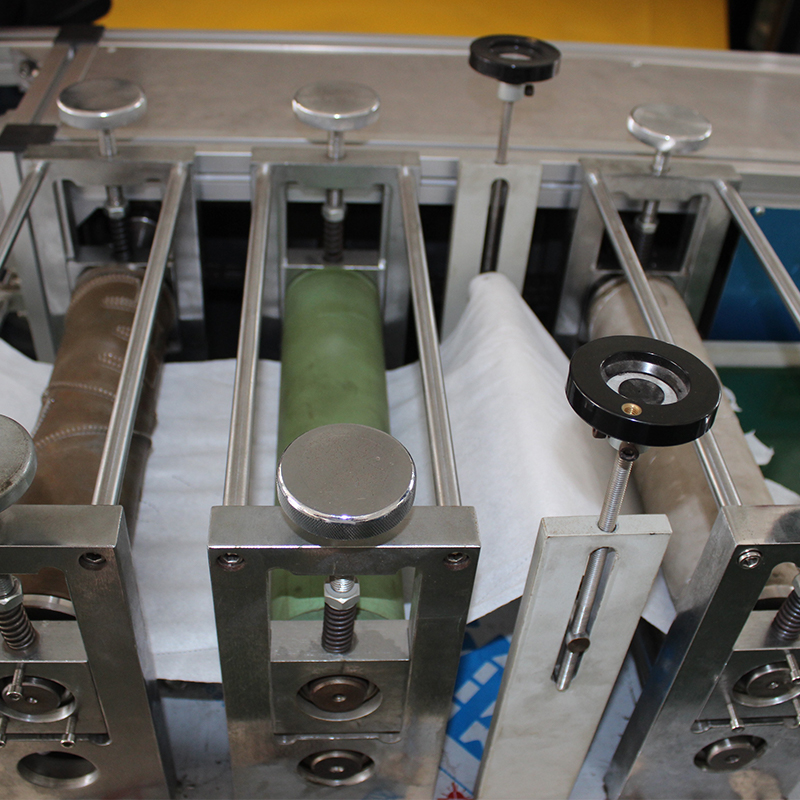

2. Ultrasonic vibration: After the ultrasonic glove machine is started, the ultrasonic

3. Welding and Forming: Under the action of high-frequency vibration, the mold, material,

4. Cutting and Separation: The formed product is cut and separated by a cutting device to

Application Fields

Ultrasonic glove machines are widely used in the processing of various non-woven fabrics, synthetic fabrics, and other materials, such as disposable cleaning cloths, shoe wiping cloths, insoles, gloves, and other products. These products have a wide range of

English

English 中文简体

中文简体 русский

русский Español

Español