Cutting Machine

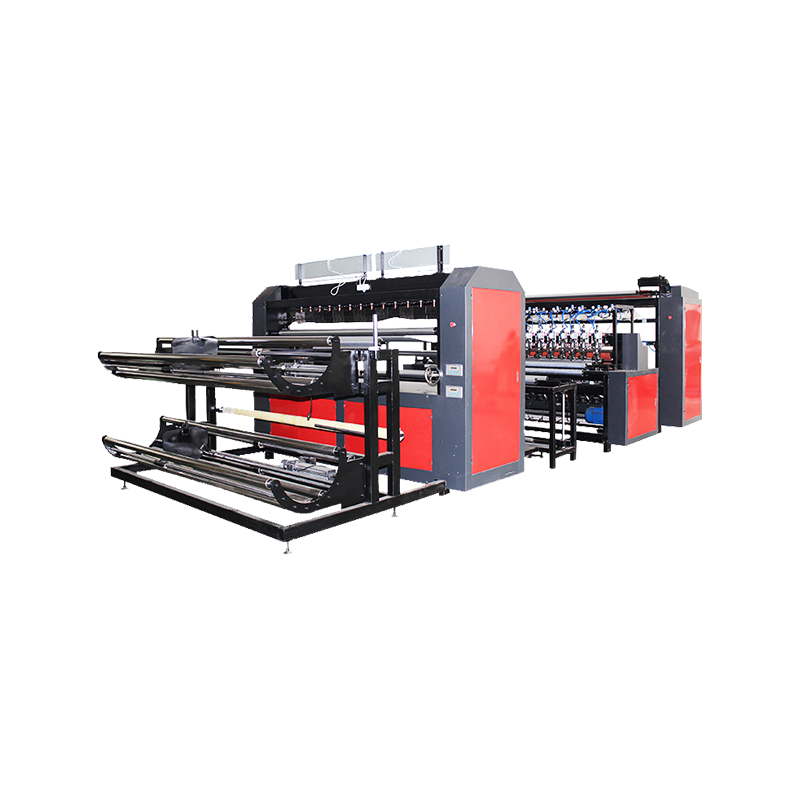

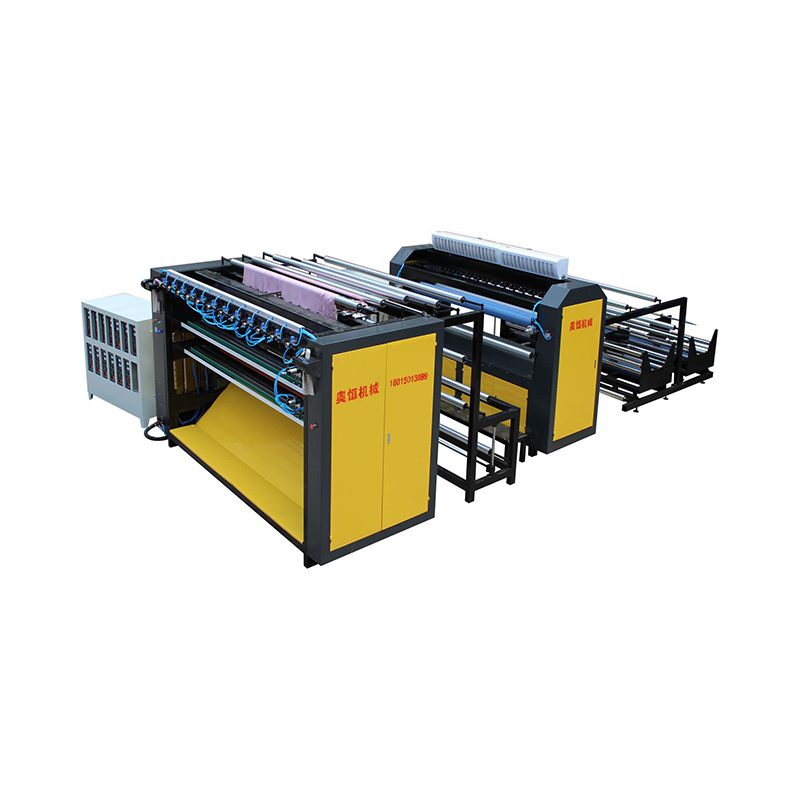

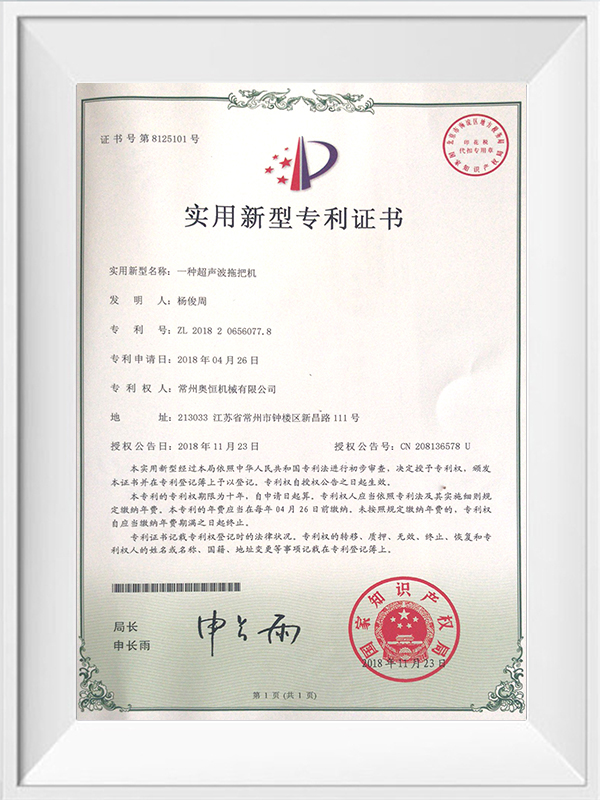

Ultrasonic composite embossing cutting machine

1、 Equipment Overview

Ultrasonic composite embossing cutting machine is a professional equipment that integrates ultrasonic technology, composite technology, and cutting technology. It mainly uses the principle of ultrasonic vibration to emboss the surface of textiles and combines composite technology to firmly bond multiple layers of materials together. Finally, the finished product is cut into the required size through cutting technology. This device has the advantages of high efficiency, environmental protection, and energy saving, and is widely used in industries such as clothing, home textiles, textiles, and household cleaning products.

2、 Working principle

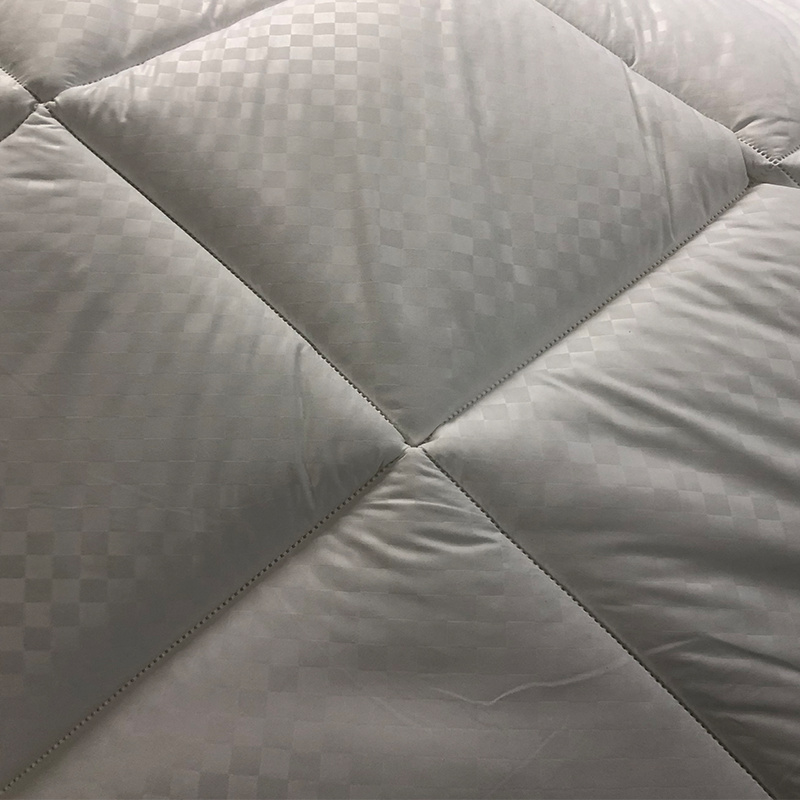

Ultrasonic vibration: The ultrasonic generator inside the equipment generates high-frequency vibration, which is transmitted to the surface of the textile through the welding head, causing the textile fibers to melt and rearrange in an instant, forming exquisite embossed patterns.

Composite technology: During the embossing process, the equipment uses special composite technology to tightly bond multiple layers of materials (such as fabrics, fillers, etc.) together, ensuring that the finished product has good structural stability and durability.

Cutting technology: After embossing and lamination, the equipment uses precision cutting mechanisms to cut the finished product into the desired size and shape, meeting the personalized needs of customers.

3、 Equipment features

Efficient production: Ultrasonic vibration speed is fast, and embossing, lamination, and cutting processes can be completed in one go, greatly improving production efficiency.

Environmental protection and energy conservation: No need to use adhesives such as glue, reducing environmental pollution and energy consumption.

Exquisite embossing: Ultrasonic embossing technology can produce delicate and uniform embossing effects, enhancing the beauty and added value of products.

Easy to operate: The equipment adopts an intelligent PLC operating system, which is easy to understand and reduces the skill requirements for operators.

Wide applicability: Suitable for embossing, compounding, and cutting processing of various textiles, such as summer quilts, curtains, sofa covers, home cleaning fabrics, etc.

English

English 中文简体

中文简体 русский

русский Español

Español