Cutting Machine

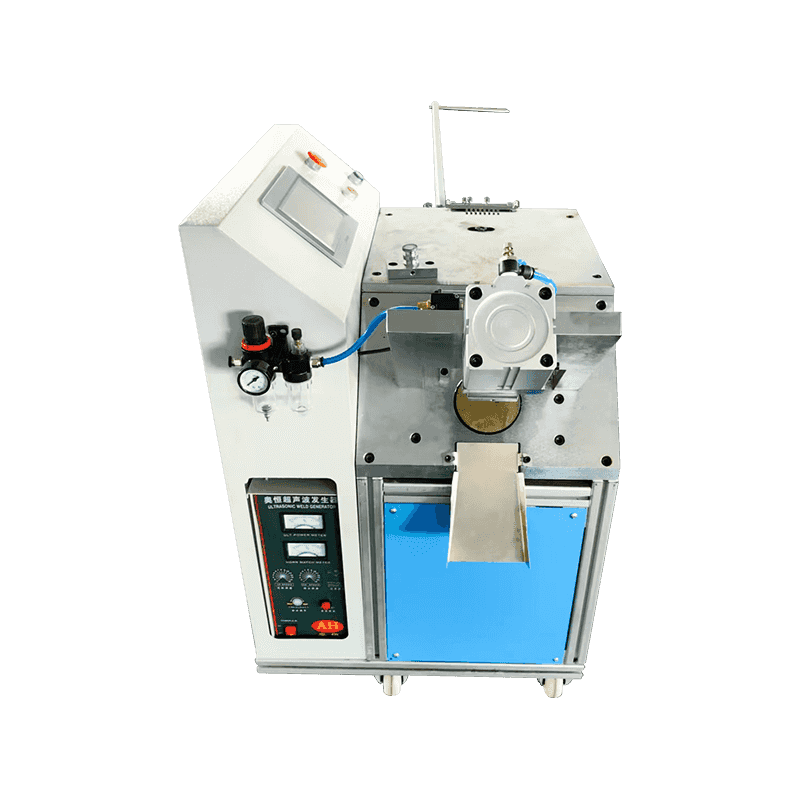

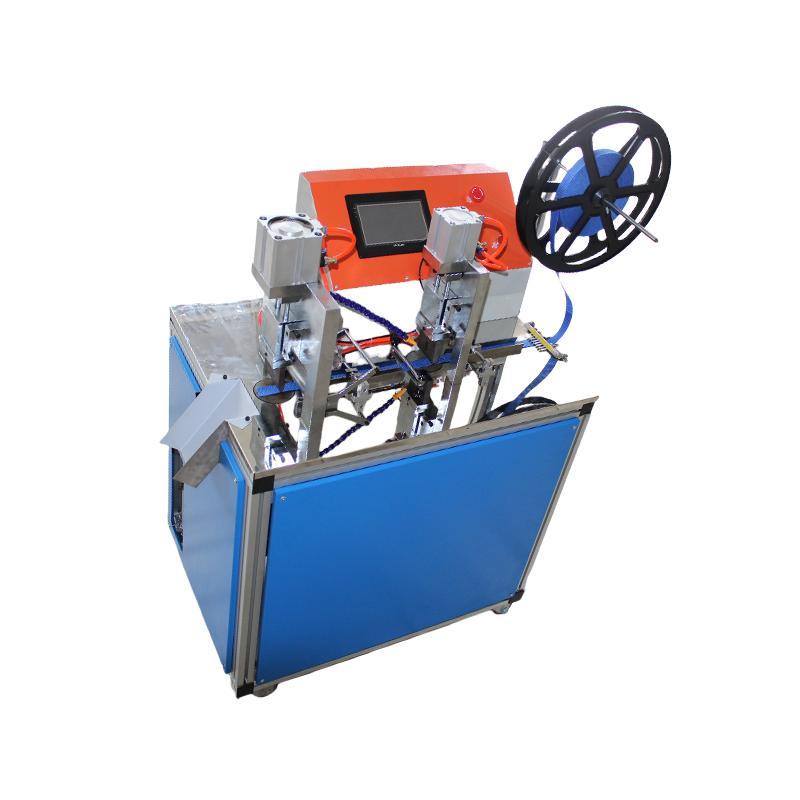

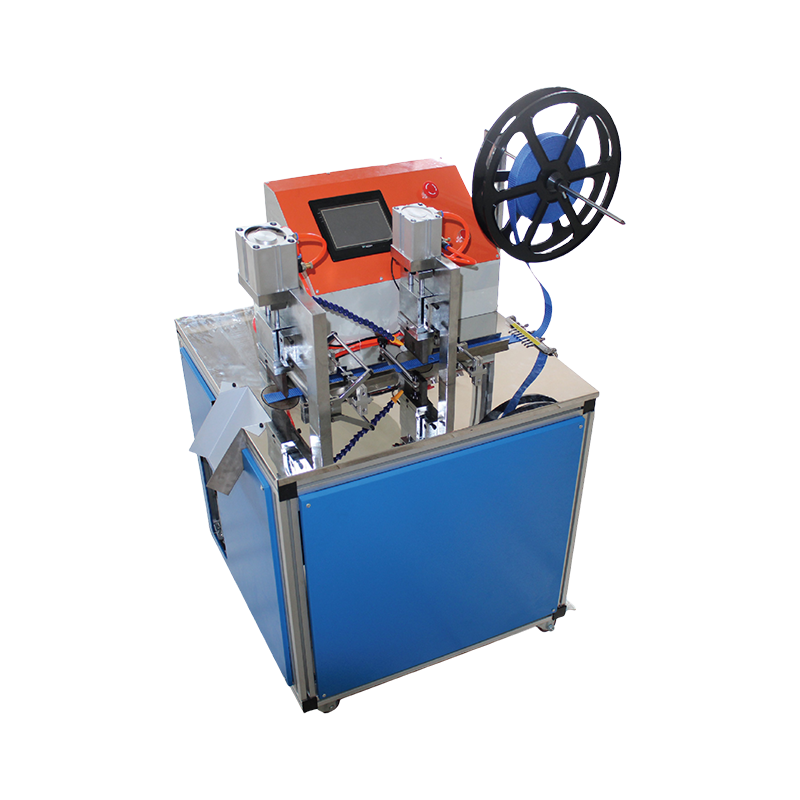

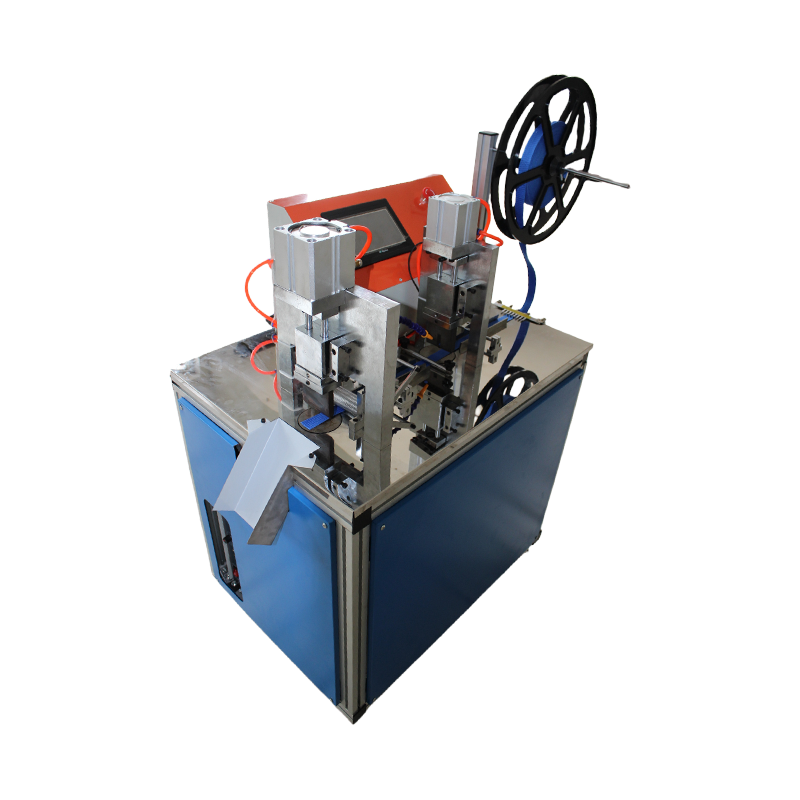

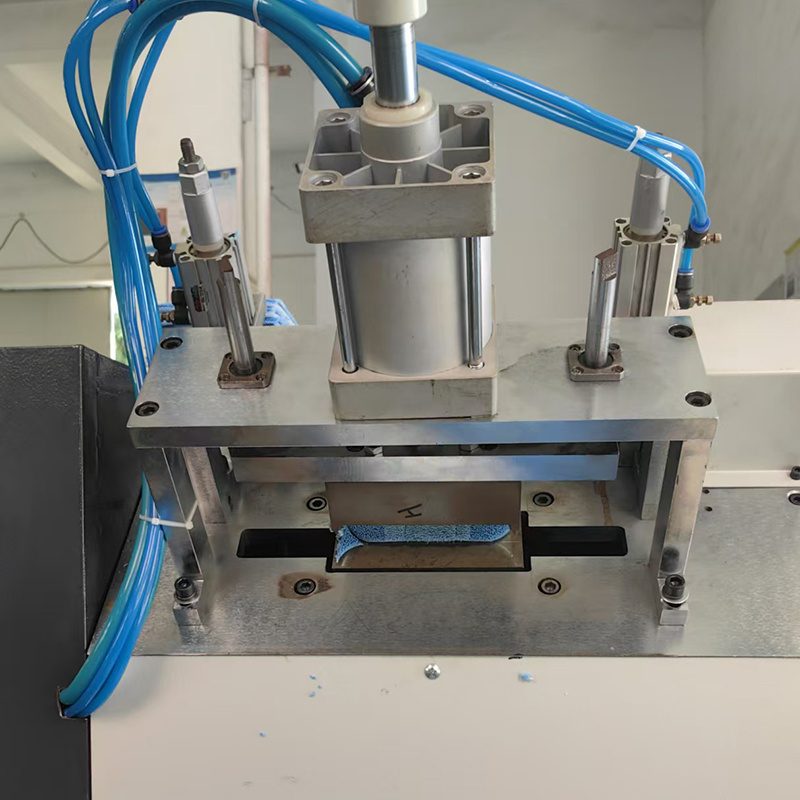

Ultrasonic belt cutting machine

1、 The working principle of the ultrasonic strip cutting machine is to transmit high-frequency vibration signals through an ultrasonic generator and ultrasonic transducer, and then transmit them to the material being cut. Under the action of high-frequency vibration, the material rapidly heats up and softens locally, while being subjected to certain pressure, thus achieving the purpose of cutting or drilling. This cutting method has the advantages of smooth incision, no loose edges, and no burrs.

2、 Ultrasonic strip cutting machines are widely used in various industries such as clothing, shoes, hats, bags, toys, gifts, packaging, etc. It can quickly and accurately cut and punch various materials of belts, meeting the diverse needs in the production process.

Product Features

1. Efficient and energy-saving: The ultrasonic strip cutting machine adopts high-frequency vibration cutting method, which has low energy consumption and high efficiency.

2. High cutting quality: The incision is flat, free of burrs, and does not have loose edges, ensuring the beauty and quality of the product.

3. Easy to operate: The device has a compact structure, a PLC operation interface, and is easy to get started with.

4. Safe and reliable: The equipment has multiple safety protection measures, and fully automatic cutting does not require manual labor, ensuring the safety of operators.

Application scope

Ultrasonic tape cutting machine is a device that uses the principle of ultrasonic vibration for material cutting, widely used for cutting and punching materials such as webbing, ribbons, ribbons, Velcro, non-woven fabrics, etc.

English

English 中文简体

中文简体 русский

русский Español

Español